After Market PART Manufacturing & Restoration Technologies

From single‑part replacements to wholesale‑ready short runs.

Scanning, Design, CAD, Prototyping, and Production.

Our Services

-

3D Scanning

High‑precision optical and laser scanning to capture exact geometry of legacy parts.

-

CAD Modeling

Reconstructing design‑intent CAD models ready for production tooling or machining.

-

Prototyping

3D printing and rapid prototyping for validation before manufacturing.

-

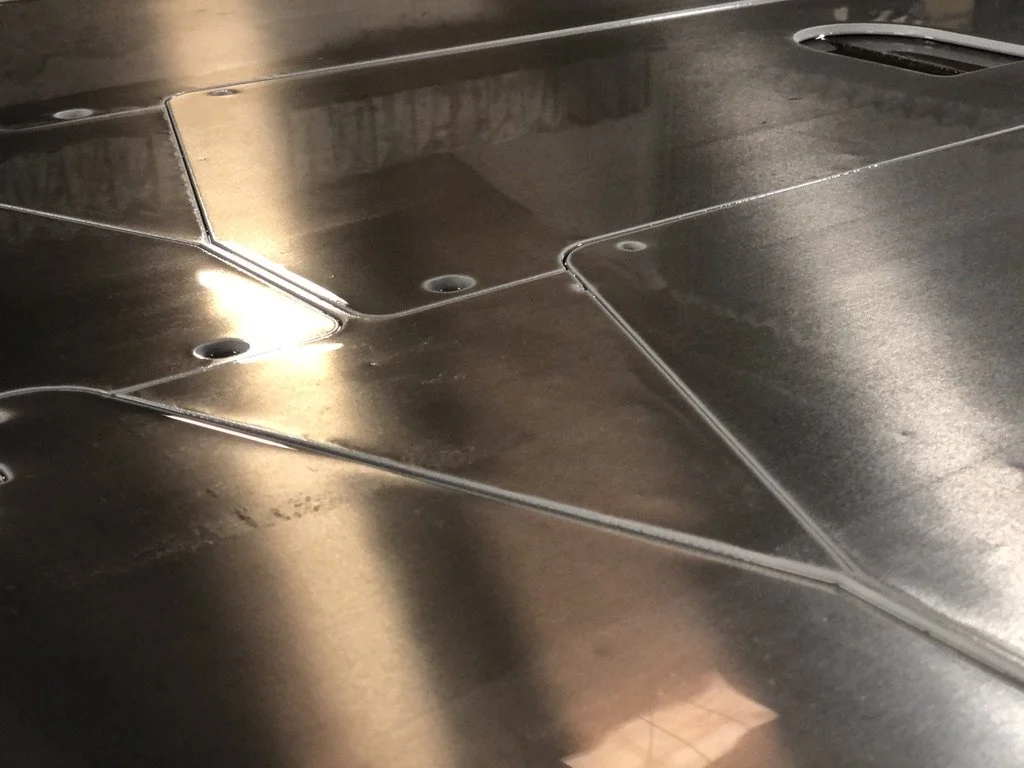

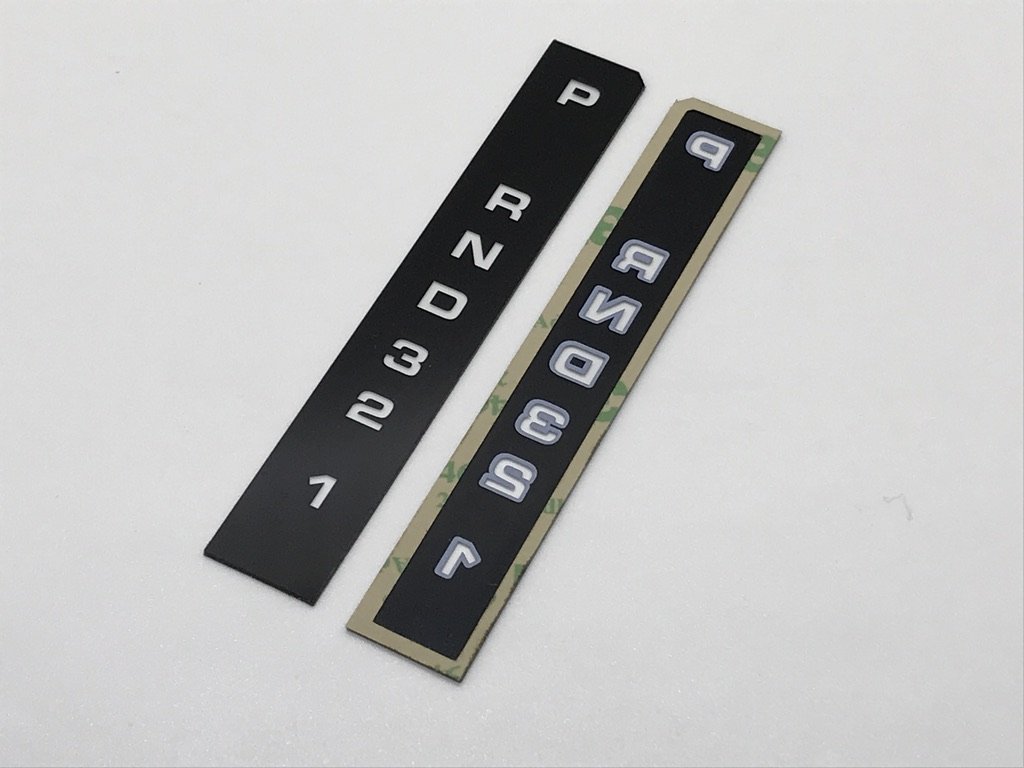

Manufacturing

Injection, Thermoforming, Blow Molding, CNC, casting, sheet‑metal — labeling, and packaging for SIOC requirements

-

Materials & Finishes

Aluminum, steel, plastics (ABS, PET, PP, NYLON) with OEM finishes

-

New Part Design & Optimization

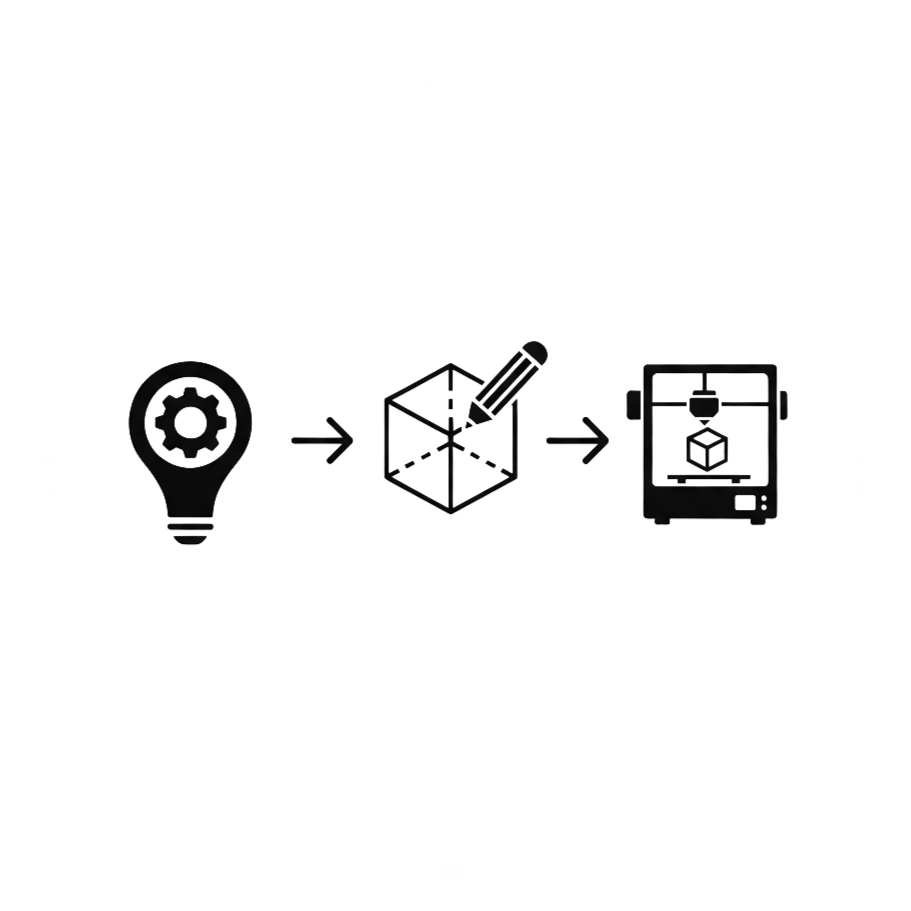

We design brand‑new components from concept → CAD → prototype, selecting materials and processes for performance, and serviceability targets.

Our Process

-

Intake

Share photos, dimensions, vehicle details, and goals.

-

Scan & Inspect

3D scanning, Research and Concept Generation

-

Design‑Intent CAD

Parametric model, GD&T, and DFM for the chosen process.

-

Prototype

Additive FDM/SLA/SLS/MJF or soft castings; fit/functional tests.

-

Production

Low‑volume CNC, casting, sheet‑metal, or molding.

-

QA & Delivery

Part review, packing and shipment

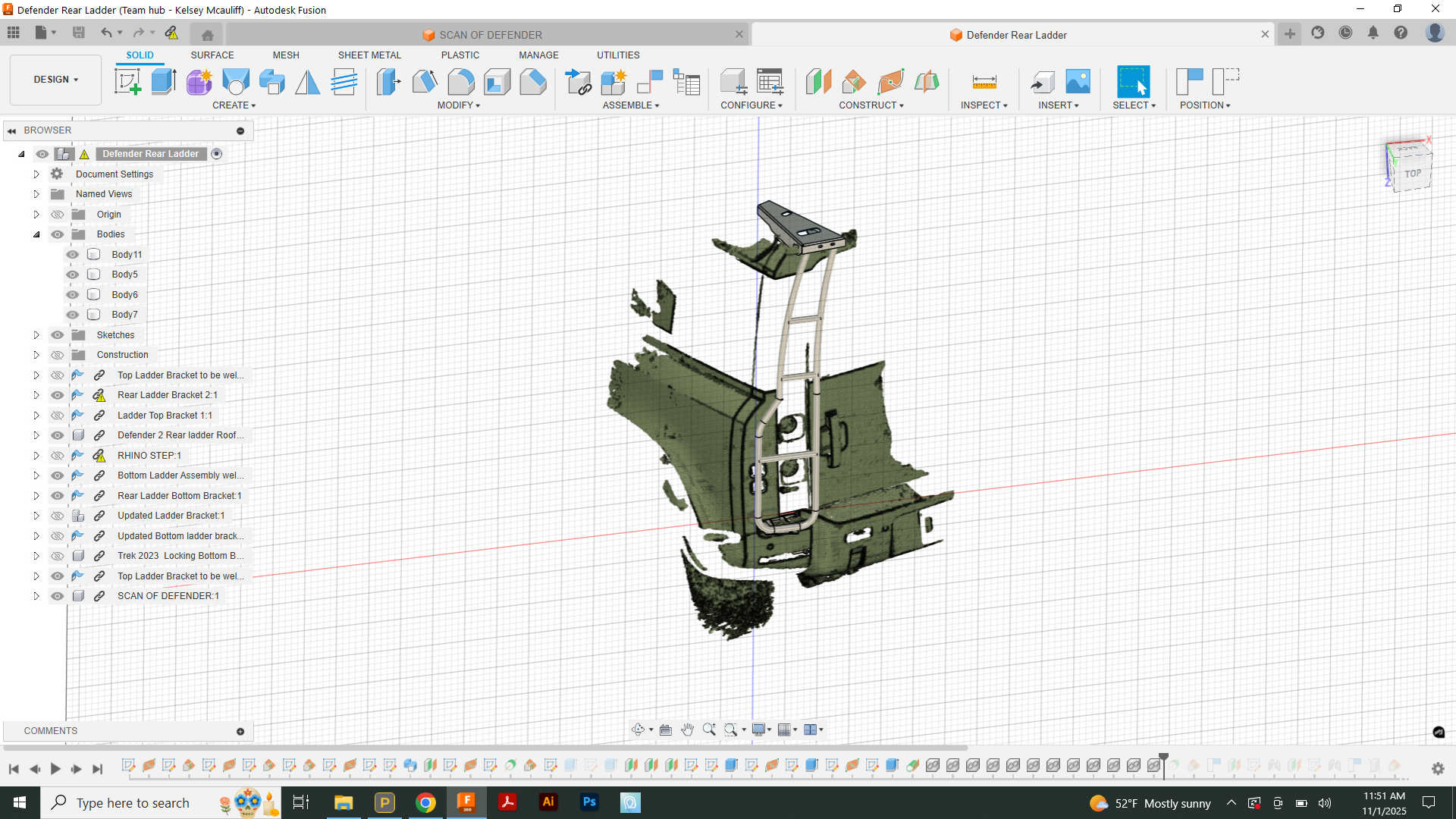

Featured Project:

Defender Ladder

Challenge

Add ladder to rear corner cap for roof access. Follow bodylines and do not conflict with lighting.

Our Process

3D scan → CAD model → 3D printed prototype → CNC-milled aluminum batch

The Outcome

Perfect fit, high durability, ready for commercial use.

Why AMPART?

Engineering, Design, and Manufacturing Expertise Combined

Experience

Design and production across multiple industries

Automotive-Grade Materials

Proven knowledge of industry standards

In-House Production

Short-run manufacturing for metal and polymer

Turnkey Solutions

No coordination between multiple vendors needed

Contact Us

Send us your hardest-to-find part — we'll show you what AMPART can do.